What's the point of them you ask? They are much stiffer than the OEM bushings and they significantly reduce the rear differential's ability to rotate when torque is applied via the driveshaft. This gives you more torque (throttle response) to the rear wheels and also helps eliminate a lot of the dreaded "clunk" in most older subarus. There's many companies including whiteline and turn-in-concepts that sells these bushings but they're only for 2002+ which won't fit 1st gen legacys.

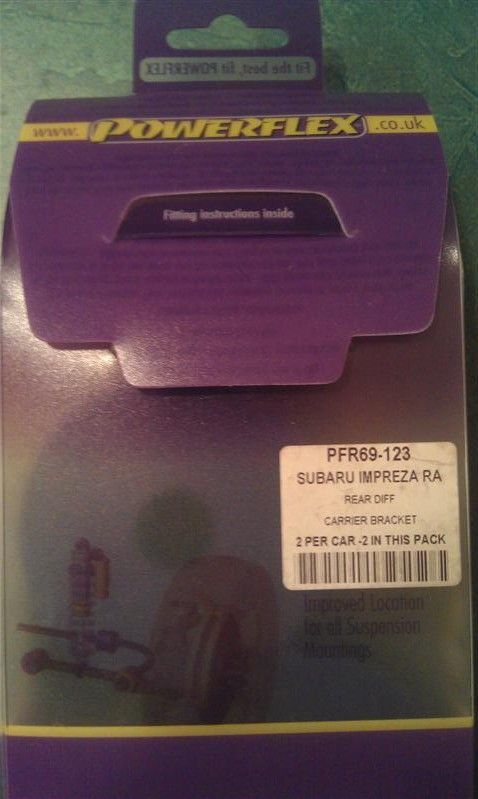

The bushings are not sold in the USA to the best of my knowledge. I stumbled across them by accident over on eBay UK. They're made by PowerFlex and they're list as "(PFR69-123) Rear Diff Mount, Early RA & UK WRX Models" but they also fit our cars because we have the same rear diff mounting bracket.

http://www.powerflex.co.uk/product-deta ... /1817.html

Only the 93-94 GC Impreza uses this bracket. 95-01 Imprezas have bushings directly in the subframe with no bracket. In 2002+ Subaru went back to the bracket but used smaller bushings and the bracket was no longer offset like ours.

So here's what $80 will get you.

Tools required to get the job done:

17mm Wrench

17mm Socket

Extension

Swivel Adapter

Hammer

Impact Gun (speeds it up but not required)

Hack Saw

Punch

2 Extra 17mm Nuts

Wire Wheel Ginder (cleans everything up while off the car; optional)

Jack your car up using blocks under the front tires and set it down on jackstands. Shake car and jack stands to make sure it's sturdy before crawling underneath.

Screw the 2 extra 17mm nuts onto the ends of the studs on the back of the rear diff. This allows you to get a wrench on the inner nuts and loosen the studs without the nut coming off. Then use your 17mm wrench to remove the 2 studs as pictured below. Make sure to support the diff with a jack before removing them all the way.

Remove the two bolts holding the bracket in the subframe. The right side bolt hits the axle so the diff must be lowered to gain clearance to pull the bolt out. I thought to myself,"Why did these idiots put the bolt in through this end if it hits the axle when you try to take it out!" Then I tried putting it in through the other side and realized it hits the gas tank.

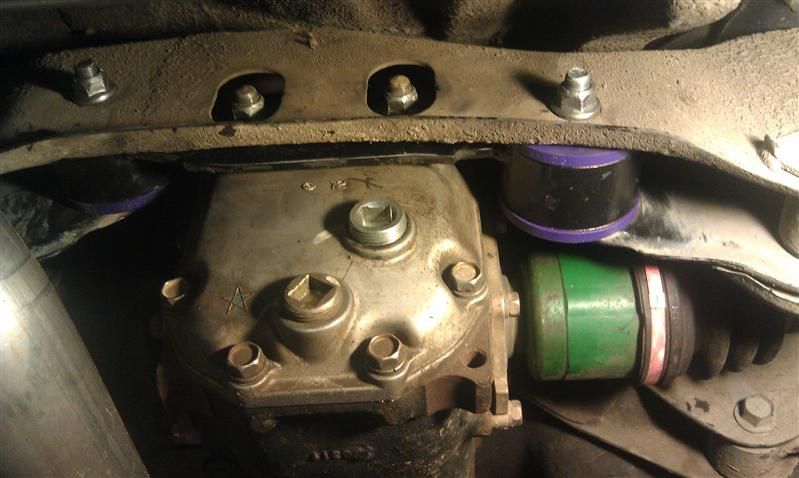

Once both bolts are removed yank the bracket out and you're left with this.

I tried using a press to remove the bushings which are housed in a metal sleeve which also has to come out and that was a major PITA and got me nowhere. Then I got the idea that I could cut the bushing out and use a hacksaw to cut the sleeve and punch it out. It worked really well. Take your hacksaw blade off and insert it through the hole in the bushing and cut both ends off. Remove the bushing and proceed to cut two slices almost all the way through the sleeve. Then use a hammer and punch to remove the piece in between. This relieves pressure of the sleeve and allows it to come right out. This is a good time to clean the bracket up nicely inside and out. Wire wheel got all the dirt and grease off easily. Careful not to remove the paint or it will rust.

Use the supplied grease to lube up the new bushings and metal bolt sleeves and pop them into the bracket.

Hard part is over. Get back under your car and jam the bracket back into the subframe starting with the left end and then insert the right side and line up the bolt holes. Insert the bolts into each end. Reinstall the diff studs before torquing anything so it's easy to get them in. Then tighten them all up really nicely by hand and go test drive your car, hopefully with much less drivetrain clunk! Killed the remaining clunk leftover after replacing my trans crossmember bushings, rear diff outrigger bushings, subframe locking bolts and driveshaft carrier bushings.