Page 1 of 2

Port and Polishing for heads, intake and exhaust-new pics

Posted: Mon Oct 22, 2007 1:26 am

by thehookeup

Subaru Cylinder Head Port & Polishing

DOHC & SOHC

Stage 1

-Basic intake deburring

-Exhaust mirror polishing

Stage 2

-Intake deburring/ enlarging

-Intake port gasket matching

-Exhaust port enlargement and mirror polish

Stage 3

-Stage 2 + combustion chamber modification and polishing

Stage 4

-Enlargement of intake ports

-Knife edging valve air splitter

-Combustion chamber modification and polishing

-Exhaust port full enlargement and mirror polish

-Intake manifold deburring

-Intake manifold enlargement to match cylinder head

-Exhaust manifold porting and mirror polishing [(depending on type of metal),

A or B]

-Valve guides must be pressed out before Stage 4 begins

Recommendations:

When having a port and polishing performed it is recommended that the cylinder heads be fully rebuilt. Though it is not mandatory on stage 1 and 2. Stage 3 and 4 it is required. The cylinder heads will subcontracted to Steve’s Precision Machine for the milling of the cylinder head surface, valve guides, valve seals, and valve seats. Steve’s Precision Machine is very experienced with Subaru cylinder heads.

Price break down

Stage 1- $225 + time dependant on whether cylinder heads are already disassembled and

need to be reassembled. 3-4 days return time if not rebuilt

Stage 2- $275 + time dependant on whether cylinder heads are already disassembled and

need to be reassembled. 3-4 days return time if not rebuilt

Stage 3- $350 + cost of machining (rebuilding of cylinder heads) 10-14 days return time

Stage 4- $800-850 + cost of machining (rebuilding of cylinder heads) 10-14 days return time

Individual services

(Available to add to any service if not included, or done individually)

-Full intake manifold deburr $100

-Full intake manifold deburr and gasket match $140

-Exhaust Manifold port and polish gasket match (dependant on whether stock manifold or after market and type of metal)

A. $100 (first 6 inches of exhaust manifold)

B. $150 (6 inches and mid pipe)

C. $350 (Full manifold including up pipe

Contact information:

Andrew Carlson

Subaru_tech@hotmail.com

971-244-3872

Posted: Mon Oct 22, 2007 2:25 am

by Adam West

This is pretty cool! When you get a web site up add the link!

Who's going first?

AW

Posted: Mon Oct 22, 2007 2:43 am

by thehookeup

i have been port and polishing for quite sometime. i should have pics soon. doug vincent can vouch for me. i do very good reliable work

Posted: Tue Oct 23, 2007 2:24 am

by mgroshong

get pics up and i would consider this more

Posted: Tue Oct 23, 2007 11:51 pm

by farfrumwork

+1 on pics (as much as they can actually show....)

Also, pricing. Maybe I'm slow today, but could you give an example of a stage 2 P&P with rebuild (including full disassembly/ reassembly) = $???

And do you do some flow bench testing of the completed heads?

I am looking to acquire a set of heads for P&P, then install at my next T-belt interval.

Thanks!

Chad

Posted: Wed Oct 24, 2007 6:44 am

by thehookeup

unfortunatly i no longer have my camera, and the past 10 sets of heads that i have done have been shipped off without pics.

i have put many sets of heads on flow benches and flow each individual intake port. i have flowed every stage and that i offer. each of which are within 5 percent or less of each other. I no longer put each set of heads on a flow bench due to the rarity and cost of flowing each cylinder. if requested i will flow bench them if it is paid for. after doing this so many times i am able to tell exactly how much material to take off.

im working on getting some pics soon. im even considering going and buy a set of heads and do a P&P just so i can get pics.

Posted: Wed Oct 24, 2007 10:00 pm

by farfrumwork

cool on the previous flow bench results, it sounds like you have it down.

Can you give us some before and after #'s from the bench test? Or just after results compared to some published flow #'s the particular heads (if you haven't done pre/post flow bench with the same heads)

i.e. ej22t heads before = ?? after = ?? (is it cc/min?) OR maybe just a % increase?

Posted: Thu Oct 25, 2007 2:23 am

by thehookeup

Stock WRX Flow

- In: 201CFM published

- Ex: 159CFM published

stage 4

- In: 247CFM+/- 5% (23% gain)

- Ex: 210CFM+/- 5% (32% gain)

those are the only numbers of mine that i could actually find. When i moved to PHX last time i left some stuff in my apartment in Oregon and my dick head of a roommate at the time cleaned out my room with out telling me.

Numbers below are approx

stage 1 percentage increase

intake 2% +/- 1% mostly for just a smoother flow

exhaust 5% +/- 1%

stage 2 percentage increase

intake 13% +/- 3%

exhaust 25% +/- 5%

Stage 3 percentage increase

intake 13% +/- 3%

exhaust 27% +/- 5%

stage 4 percentage increase

intake 23-25% +/- 5%

exhaust 32-40% +/- 5%

i remember that i have had greater flow increases than those. But without physical proof, i would hate to have myself throw out some number that i might not be able to back up.

On one set of stage 4 heads that i did, i completely ground off the protruding valve guide that was in the intake and exhaust ports. seemed to flow well when they were on the car. i have no numbers for it but. it was interesting

Posted: Thu Oct 25, 2007 2:42 am

by douglas vincent

The last set Andy did was for me that I sold to a guy in Kentucky. He just recieved them, but UPS DROPPED THE CRATE AND IT BROKE OPEN AND ALL THE FLIPPING CAM CAPS WERE LOST!

The PnP was nice though. But I forgot to take pictures.

Posted: Thu Oct 25, 2007 7:53 am

by Arctic Assassian

holy shit, I would prolly sue them for slander.

Posted: Thu Oct 25, 2007 6:36 pm

by thehookeup

yea this ups thing pisses me off so much. im still salty about it. but doug did insure the boxes thank god.

Posted: Fri Oct 26, 2007 8:36 pm

by farfrumwork

Cool. Thanks for the info Andy. Sounds like some solid increases in flow.

I'll keep this in my pocket until I find some used heads to get worked (and $ for it all)

Posted: Thu Nov 15, 2007 8:09 am

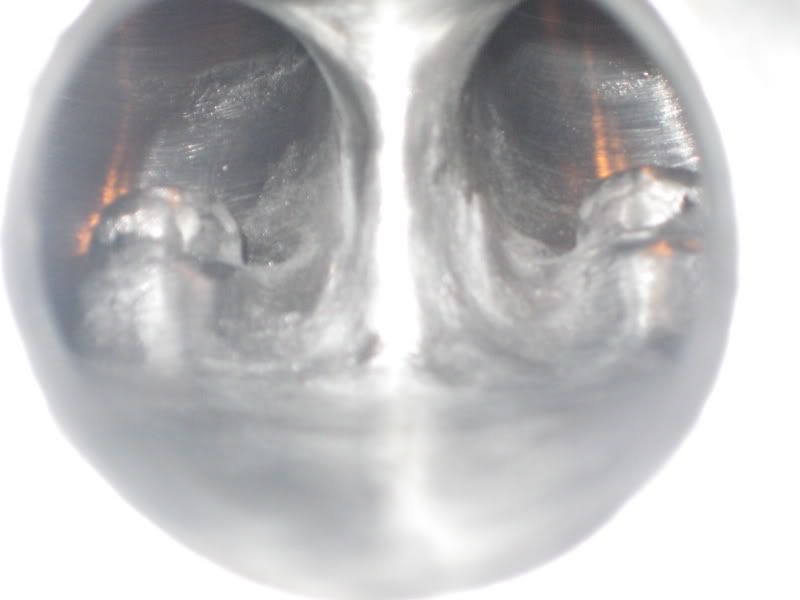

by thehookeup

P/P ej22t heads

Posted: Tue Nov 20, 2007 8:01 pm

by rockethound

Is it worth doing a P/P on ej22t heads? If so, to what extent? Eventually I'll get around to picking up a set of ej20g heads but the 22t is being rebuilt soon and that's what I have to work with now.

Jeff

Posted: Fri Nov 23, 2007 8:19 am

by thehookeup

i have done a few stage 2's on 22t heads. Any port and polishing helps always does. They flowed great and seemed to help a little for a stock build. but if you are planning on doing 20g heads on your 22t p & p those heads you would see a bigger difference

Posted: Fri Nov 23, 2007 9:53 am

by 555BCTurbo

I hope you don't polish the intake side of the heads...

Porosity = fuel atomization =

Posted: Fri Nov 23, 2007 3:29 pm

by evolutionmovement

But you don't want fuel sticking to the intake wall either.

Posted: Fri Nov 23, 2007 6:31 pm

by 555BCTurbo

evolutionmovement wrote:But you don't want fuel sticking to the intake wall either.

True...but I have never heard of that being a problem...

I think Cosworth has the best idea, as they cast in small raised sections in the intake ports of their Subaru heads for proper atomization.

Posted: Fri Nov 23, 2007 7:17 pm

by bmxpunk

Sent pm Interested in having my intake manifold done.

Posted: Fri Nov 23, 2007 8:08 pm

by thehookeup

no i dont polish the intakes, that can mean bad bad bad news. just porting. gotta leave it rough. i have heard of that cosworth idea, does anyone have any pics?

Posted: Fri Nov 23, 2007 10:44 pm

by evolutionmovement

I wonder if something like a hexagonal golf ball texture would be the best bet. I would think the small turbulence would reduce surface drag and contribute to a smoother flow in the main portion of the manifold. Can't figure if it would be better or worse for fuel atomization. Experimenting would be very expensive. Direct injection would be nice.

Posted: Sat Nov 24, 2007 11:45 am

by thehookeup

shoot that golf ball idea could be amazing but your right it would cost so much to test. if it works for a golf ball it could work for anything. physics are physics. keeps it stable and flows well. but i cant imagin the machining that could go into something like that. def a CNC with someone thats a god at the controls. great idea though surely out of my reach

Posted: Sat Nov 24, 2007 5:04 pm

by evolutionmovement

Something like a rapid prototyping process on a plastic that would work in an engine environment might be the only way. Current tests show that it works best on spinning and curved surfaces, so I'm unsure if it would help throughout the manifold (like straight sections). On bicycle wheels it reduces leeward drag (at the expense of a small increase in surface drag) and on golf balls it allows the air to stay attached to ball longer (almost making it act like more of an aerofoil shape that is always correctly oriented to the direction of travel), reducing the separated wake on the ball (drag). So covering a car with hexagonal dimples would only help in some parts depending on the shape of the vehicle since skin friction tends to be a greater problem than pressure differential and the increase in skin friction would actually create more drag. Skid542 could explain this much better.

Posted: Sun Nov 25, 2007 1:36 pm

by mgroshong

there is a guy that own's endyne energy dynamics, he used to dimple the intake side of heads for hondas, and it made improvment in fuel atomization.

if i could find more info on this i would post it up.

Posted: Sun Nov 25, 2007 8:50 pm

by 555BCTurbo

mgroshong wrote:there is a guy that own's endyne energy dynamics, he used to dimple the intake side of heads for hondas, and it made improvment in fuel atomization.

if i could find more info on this i would post it up.

Endyn does some pretty amazing stuff with Honda motors...they really have chamber design down to an art

Like 800whp B18...that's pretty impressive