Page 1 of 1

N1446' s Build Journal Post

Posted: Wed Apr 15, 2009 4:32 am

by N1446

>> This page is taking over the build page for a while as the EJ2.34t project is on hold.

Updates below

Posted: Thu Jun 25, 2009 6:57 pm

by N1446

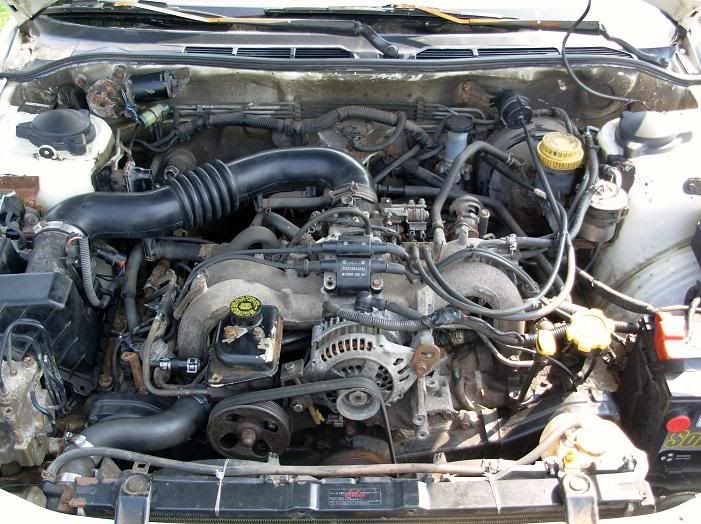

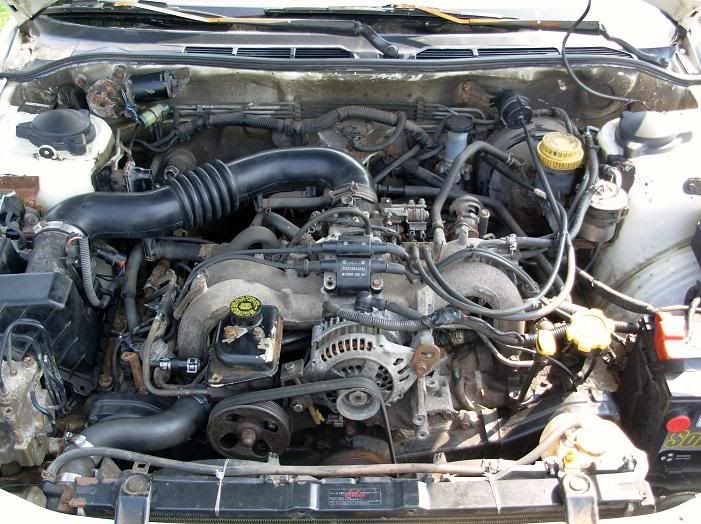

- EJ25D installed in a MY'91 turbo Chassi + ECU

I almost forgot ,, Installation is the reverse of removal - SSeriously though it not so bad

- 22T5mt items swapped onto phase 1 EJ25D engine

-

pwer steering pump

alternator

MAF

flywheel cover plate - under-side

-

22T5mt manifold items swapped onto EJ25D engine

-

22t throttle body w\c position sensor

22t idle air control valve

22t ignitor

22t purge control solenoid

-

22T5mt harness modification includes :

-

extending engine coolant temperature sensor clip to opposite side } on coolant crossover

-

extending temperature sensor clip to opposite side } on coolant crossover

-

knock sensor : switching connector style to EJ25D type, to accomidate the knock sensor on 25D

-

22t crank sensor : switching connector to EJ22t style to accomidate 22t harness

-

22t cam sensor : switching cam sensor to EJ22t style to accomidate 22t harness

-

neutral items \ universal fit both harness

-

injectors 1 2 3 4

oil pressure switch

engine coolant temperature sensor : needs harness extention

temperature sensor : needs harness extention

-

EJ25D engine items remain

-

knock sensor

crank sensor

-

EJ25D intake manifold items remain

-

injectors 1 2 3 4

vaccume \ Intake tubing

-

OTHER PARTS NEEDED TO SWITCH TO EJ25 > 5mt

***

5mt intake hoses

***

UN USED PARTS AND SENSORS ON EJ25D > auto

***

Tourque convertor

EGR valve - i created a false valve gasket and bolted the EGR Valve back on over-top the false gasket with a high temp gasket sealer + capped plumbing

EGR valve solenoid removed + capped plumbing

-

***

UN USED PARTS AND SENSORS ON EJ22T-5mt

***

Charcoal canister removed

Turbo exhaust manifold removed

-

Extra Parts Involved **

--

98 GT engine fans

98 GT engine coolant overflow tank

- here is a video of the 25D start-up , there is no exhaust though the car idles fine without the o2 sensor

engine start

Posted: Sun Dec 06, 2009 7:13 am

by N1446

Soo this weekend between a 3000 word paper and a site report, i scurried up enough courage to pull the motor out and drop a new engine crossmember in right before work .. .. ...

yeahh rrighttt

i prop'd the car up and whipped out the angle grinder and ripped out an inch off the crossmember.

may as well i just file it down a bit right ? - , and i do mean a bit

i m quite sure there is no loss of integrity here on the c-member

-

+

+

above is the exhaust installed ,

gasket maker and the gaskets that arrived with the exhaust make a great seal

-

i did have to remove the front swaybar for this exhaust to fit , headers are OBX for a '98-'05 impreza 2.5 RS

not a huge deal , all this is temporary until the real motor is built

it sounds BeefY !

like chunk'i soup beefY!

next is finishing up on the rest , cut and paste sorta stuff

Posted: Wed Dec 23, 2009 5:27 am

by N1446

Vclip of 0-60, then 60-100^^

3/4 throttle

Quality is a bit rough.. the exhaust is yet to be sealed, so its a bit loud still.

next is plugs& wires

Posted: Wed Dec 23, 2009 5:14 pm

by SILINC3R

how much for those headers and do you have a part number available. thanks

Posted: Thu Dec 24, 2009 12:31 am

by N1446

part number # H10798

cost 299US on ebay right now

ebay item number # 200411172559 from seller : dialod

Posted: Thu Dec 24, 2009 3:55 am

by SubaruNation

that sounds legit!

Nice!

Posted: Sun Jan 03, 2010 11:04 pm

by SILINC3R

so you said you had to remove the sway bar, is that permanent

Posted: Mon Jan 04, 2010 6:24 am

by N1446

SILINC3R wrote:so you said you had to remove the sway bar, is that permanent

as far as i can tell yess it is permanant, i have a turbo front swaybar and the bends colide with the pipe

non-turbo may be a different story

Re: N1446' s Build Journal Post

Posted: Thu Aug 05, 2010 2:09 am

by N1446

heay again here is the latest updates on the engine "upgrade"

I m tearing out the current EJ25 over the next two weeks for a younger prettier 2.5 from this 98 forrester S .. the red one

over the winter the legacy over-heat and threw a rod.. yess another one

I also have some pictures of the finished exhaust after one winter, as you can see, the new headers fit to the existing chassi and also the cat-back portion is from a '98 legacy/outback, this is stock equipment on all the stock mounting hangars with a subaru mufler . IMO No easier upgrade than this for novices and a huge difference for off-the-line ie; no stumbling starts in place of the original equipment .

I' ll see if the front sway bar on the forester will fit the legacy now with the new headers -cause that would be sweet.

Re: N1446' s Build Journal Post

Posted: Mon Aug 16, 2010 6:51 am

by N1446