Lightweight Speaker Enclosure Project

Posted: Fri Feb 26, 2010 7:03 am

Recent discussion (elsewhere) has lit a fire under my ass to work on the sound system for the hot rod. I miss having a little bit of bass in my car, but the weight troubles me. My old box was really heavy, so I've sworn off MDF. This leaves me in a bit of a predicament, since few materials hold up to the abuse of a decent subwoofer and keep the pounds down.

I've seen plenty of fiberglass boxes built to look damn sexy, but they end up being almost as heavy as their MDF counterparts. The main problem in their construction is the many layers of glass it takes to achieve the rigidity necessary for a sub enclosure. I plan to challenge that methodology.

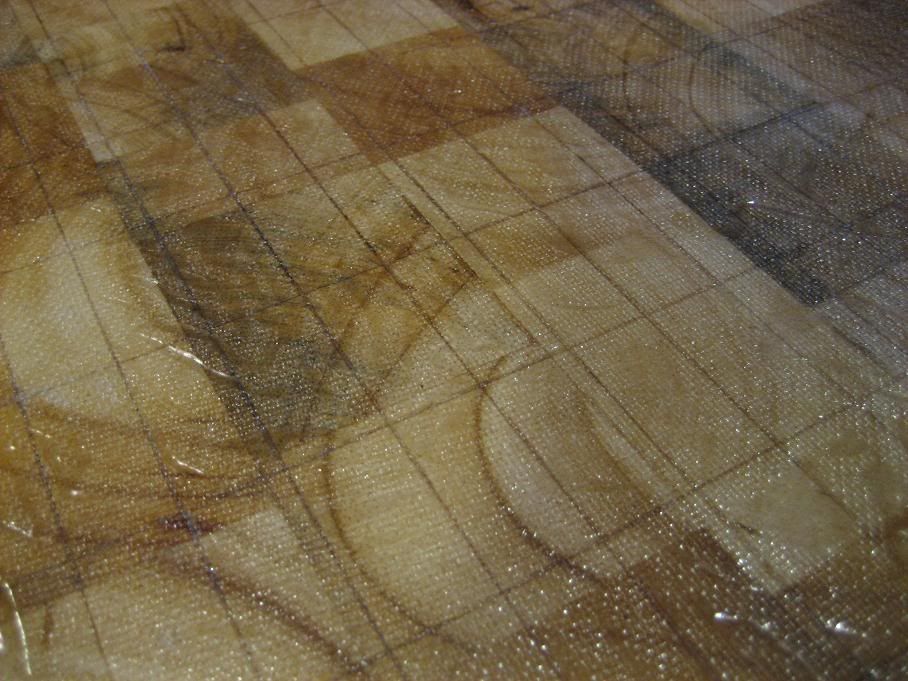

The key in my approach is sandwich construction. The further one can separate the layers of a composite structure, the stiffer it will be. As little as 1/4" of separation can mean as much as five times the stiffness of the same two layers of a composite. In the picture below, we made samples with 10 oz plain weave carbon fiber. 10 oz is rather heavy carbon and difficult to work with. Anyways, the picture below shows the samples we made. The sample without a core took 25 lb to bottom out the test rig at 1". The second sample with a 1/8" core took 75 lb to yield, and the last sample with 1/4" core took 125 lb to yield. I'll be using a 3/8" core.

I'll be using 3/8" balsa as a core, 7 oz plain-weave E-glass for a base inside and out, and then 5.7 oz plain weave carbon for the outside. I wanted a 2x2 twill weave for the carbon, but Express Composites in Minneapolis was out of it and I didn't want to wait. I'll just have to radius the outside edges for the plain weave.

All said and done, the materials came to about $120.

I also stopped at my dad's house to use his router to make a 3/8" ring for mounting the sub. Balsa would struggle to hold screws, so a 1" MDF ring for mounting is necessary.

I decided to go with a basic sealed box, even though I prefer the sound of a vented enclosure. Making the box sturdy enough to introduce a vent is not something I want to get into the first time around, so I decided to leave it out. When I figure out how to vacuum bag something like this, I might build a vented box.

The subwoofer is an Alpine Type R from about eight years ago. It is a single 4 ohm voice coil sub that worked well with the Rockford 250a2 amp I had at the time. That amplifier has since bit the dust.

This is the old box. It has been a parts shelf for six years, and spent four years in my trunk before that. The outside is getting a little beat, but it still works. 16 pieces of MDF comprise the box. The vent is built into the box with the proper cross-sectional area and length. The window was a hair-brained idea since you can't see it with the box in a car. It sounded like a good idea when I was 20 years old, though. Anyways, the box is a pig and I want nothing to do with it in my hotrod.

For the rest of the system, I have on hand (by accident) four Alpine Type S 6.5" full range speakers. I plan on powering them with a four channel Xtant amp I already have. I need a head unit still, and I've been thinking about an old Alpine unit that has decent pre-amp outputs and is simple. I don't need a fancy display or anything like that. Just something reliable and three sets of decent pre-outs. I'm also looking for a sub amp in 250w RMS range.

I've seen plenty of fiberglass boxes built to look damn sexy, but they end up being almost as heavy as their MDF counterparts. The main problem in their construction is the many layers of glass it takes to achieve the rigidity necessary for a sub enclosure. I plan to challenge that methodology.

The key in my approach is sandwich construction. The further one can separate the layers of a composite structure, the stiffer it will be. As little as 1/4" of separation can mean as much as five times the stiffness of the same two layers of a composite. In the picture below, we made samples with 10 oz plain weave carbon fiber. 10 oz is rather heavy carbon and difficult to work with. Anyways, the picture below shows the samples we made. The sample without a core took 25 lb to bottom out the test rig at 1". The second sample with a 1/8" core took 75 lb to yield, and the last sample with 1/4" core took 125 lb to yield. I'll be using a 3/8" core.

I'll be using 3/8" balsa as a core, 7 oz plain-weave E-glass for a base inside and out, and then 5.7 oz plain weave carbon for the outside. I wanted a 2x2 twill weave for the carbon, but Express Composites in Minneapolis was out of it and I didn't want to wait. I'll just have to radius the outside edges for the plain weave.

All said and done, the materials came to about $120.

I also stopped at my dad's house to use his router to make a 3/8" ring for mounting the sub. Balsa would struggle to hold screws, so a 1" MDF ring for mounting is necessary.

I decided to go with a basic sealed box, even though I prefer the sound of a vented enclosure. Making the box sturdy enough to introduce a vent is not something I want to get into the first time around, so I decided to leave it out. When I figure out how to vacuum bag something like this, I might build a vented box.

The subwoofer is an Alpine Type R from about eight years ago. It is a single 4 ohm voice coil sub that worked well with the Rockford 250a2 amp I had at the time. That amplifier has since bit the dust.

This is the old box. It has been a parts shelf for six years, and spent four years in my trunk before that. The outside is getting a little beat, but it still works. 16 pieces of MDF comprise the box. The vent is built into the box with the proper cross-sectional area and length. The window was a hair-brained idea since you can't see it with the box in a car. It sounded like a good idea when I was 20 years old, though. Anyways, the box is a pig and I want nothing to do with it in my hotrod.

For the rest of the system, I have on hand (by accident) four Alpine Type S 6.5" full range speakers. I plan on powering them with a four channel Xtant amp I already have. I need a head unit still, and I've been thinking about an old Alpine unit that has decent pre-amp outputs and is simple. I don't need a fancy display or anything like that. Just something reliable and three sets of decent pre-outs. I'm also looking for a sub amp in 250w RMS range.