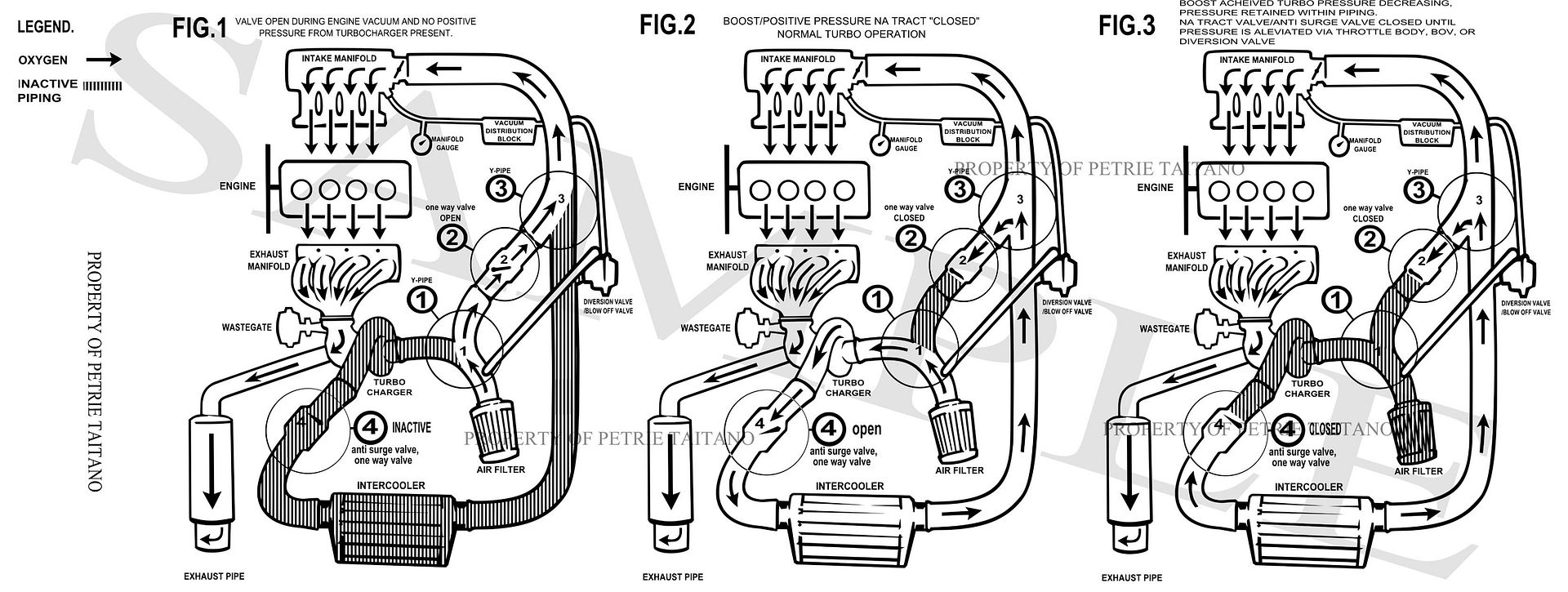

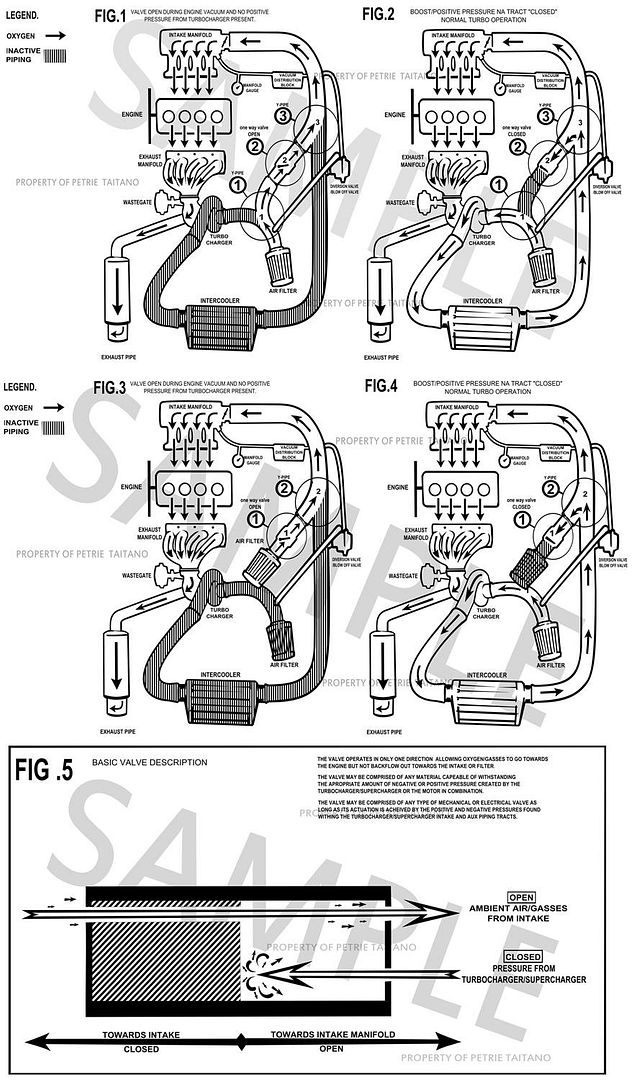

It seems to make sense to me but I'm not that smart so perhaps you guys with more knowledge of turbo systems can give some chime in here. The basic idea is to bypass the compressor wheel of the turbo with a diverter valve allowing the engine to act more like a naturally aspirated engine initially and then once the turbo has spooled to a point where it's creating positive pressure in the intake system, then the valve closes to change the path of airflow back through the compressor like normal. He says the compressor wheel and turbo is creating a restriction in the intake and that bypassing it will allow the turbo to spool quicker and make more power in the low end before the turbo kicks in.

His name is Petrie Taitano. Here's a clip of text he wrote on a video (can't share the video because you have to be friends with him to see it on facebook) demonstrating the valve in action on his car.

"about an invention i was working on...so with a bit of thought about what i had been working on so hard but never actually was able to do anything with due to financial ability, some peoples stubborn idiotic nature refusing to even look at it because im some nobody.

also it has hit the time frame where it has become public domain and un patentable... so it is what it is

i have also struggled with sharing this.. but i would rather you saw this from me than some butthole at some performance shop..

what i had been working on was a way to provide oxygen to the engine without bottle necking it at the turbo which most of the time at a dig or while taking off without break boosting or pre-spooling and it isn't spinning enough to provide any real air or oxygen, even when you mash the gas pedal.. theres still a lack of time in which the motor gets that suppressed feed of air and in turn finally spins up the turbocharger.

this effect is more drastic as you up-size the engine liter or displacement vs the turbocharger sizing..

one friend reported a 700 rpm spool time decrease with a much larger turbocharger.. i have the opposite a mid range 60 ish ar turbo.. and because of this it spooled at a stop just blipping the gas.. with a light weight flywheel and in neutral.

but literally what i was working on i guess had been semi developed before in a small part by a guy named dan caulkins and unknown to me the fact that it had been thought of about 8 years prior.. the difference well the difference was.. his valve idea used an intake and valve that had almost a maximum of a 1 inch orifice... unknowingly i developed a very similar system that used an almost 2 inch intake orifice an unsprung valve (his was sprung which defeated some of the vacuum relief ).. which seems not so amazing until you start seeing how it worked in total..

the end result of his work was the general idea and thought that it would never work.. people dogging the idea and generally calling the "d valve" a joke that did fuck all.. and the reason is no one bothered to take it to the practical level or do any real digging..fixing flaws restrictions and diameters. as i have done..

so instead of nay saying and crap i was met with enthusiasm. from people in varied Fields.. engineers, tradesmen, etc... none of which could argue it in a bad or negative way.. and quite the opposite most agreed it could only assist and it has..

example:

imagine an ls (corvette engine) with a decent sized turbo.. in most cases.. the car needs some serious revving or brake boosting in order to spool or even take off with any force...with this device yeah you can still brake boost rev, but what you can do is punch the gas without any of that... and the engine just works like a non turbo car because until the turbo creates boost it is a non turbo car with this item.... in fact because of this the turbo snaps into function faster because the motor can load up the cylinders and manifold faster... much much faster.

seems stupid and simple but in reality its what it is.. something that worked well enough for me to walk on subarus, mercedes amgs, boosted civics, evo's, etc..

so think im crazy if you want.. but the proof is where it is.. i will post some vids showing it work.. just remember they are old.. and yeah that manifold is what it was.. a leaky piece of crap.. now imagine knowing that it was horribly leaky and i could still spool by just hitting the gas,

one last thing to observe. in this video you see the valve actuating like mad.. well if the turbocharger was ever providing more air than the motor needed that flap would NEVER OPEN....enjoy"

"heres something i was working on because my car did that same shit when i first boosted it.

the drawing and diagrams in the comments explain a lot of how it works. but in reality a turbocharged engine relies on a spooled turbo to breath. unfortunatley most turbochargers need to spool to allow air to even let the motor idle..

i did a test on a friends 2jz we hooked up just the coldside to see if the car would even idle.. with a stock na exhaust.. the car would not start"

Here's the valve he's using : http://www.ebay.com/itm/NEW-JANDY-7305- ... 1e8e04b895

Here's his build thread on the TC : http://www.scionlife.com/forums/regiona ... al-229358/

Here are a couple diagrams he made of how the system functions and a shot of his engine with the valve installed and operational.