UHEV Legacy Version 2.0

Moderator: Moderators

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

The pictures of the white car are of Whitelegacyguy's car. That stuff is long gone on mine. I even welded the hole on the firewall shut, lol.

Last edited by 93forestpearl on Thu Oct 15, 2009 8:15 pm, edited 1 time in total.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

SubaruNation

- Fifth Gear

- Posts: 3526

- Joined: Wed Jul 18, 2007 5:07 pm

- Location: Whammy!

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

-

SubaruNation

- Fifth Gear

- Posts: 3526

- Joined: Wed Jul 18, 2007 5:07 pm

- Location: Whammy!

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

-

SubaruNation

- Fifth Gear

- Posts: 3526

- Joined: Wed Jul 18, 2007 5:07 pm

- Location: Whammy!

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

^ Thanks for the props.

I haven't had much progress lately because baby needs camshafts and a plate or two for the clutch. I'll work on the engine bay this week, installing the pedal box, brake master cylinder, clutch master, lines, some wiring, etc.

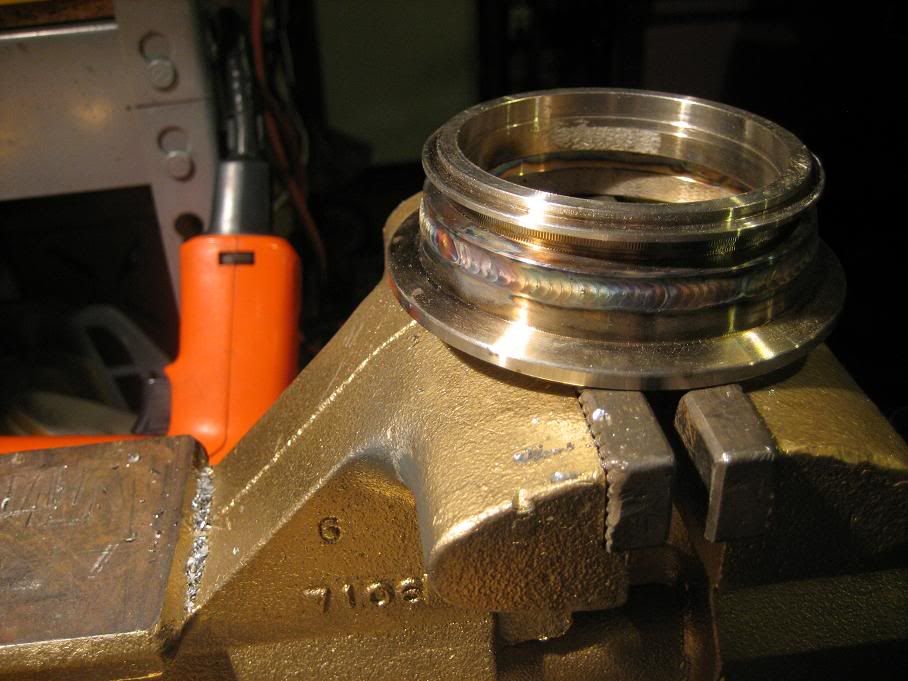

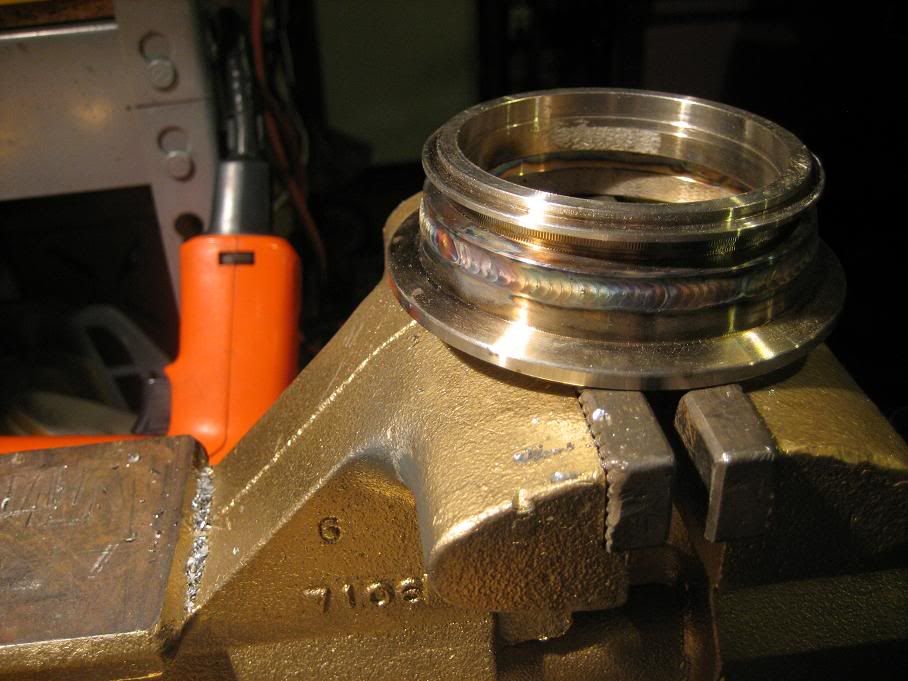

The other day I disassembled the turbo for cleaning. I'm not sure if it needs to be apart for balancing, but I'll find out tomorrow. Anyways, she's in pretty nice shape. No play or scoring on the bearings, and it happens to have a 360 degree thrust bearing. I was surprised as to how heavy the turbine wheel is. Its crazy that it spins up to 115,000 rpm.

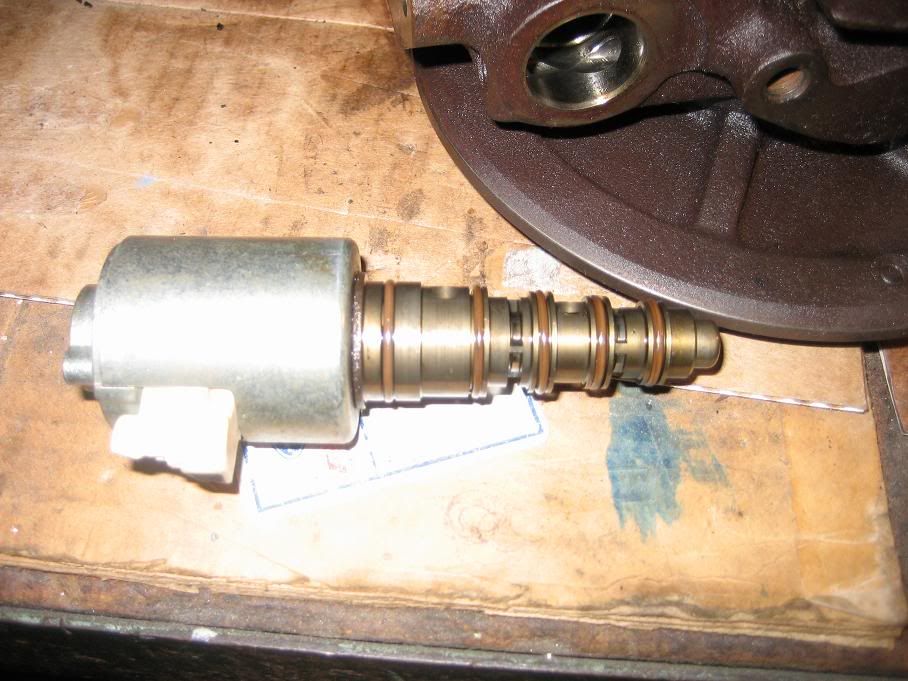

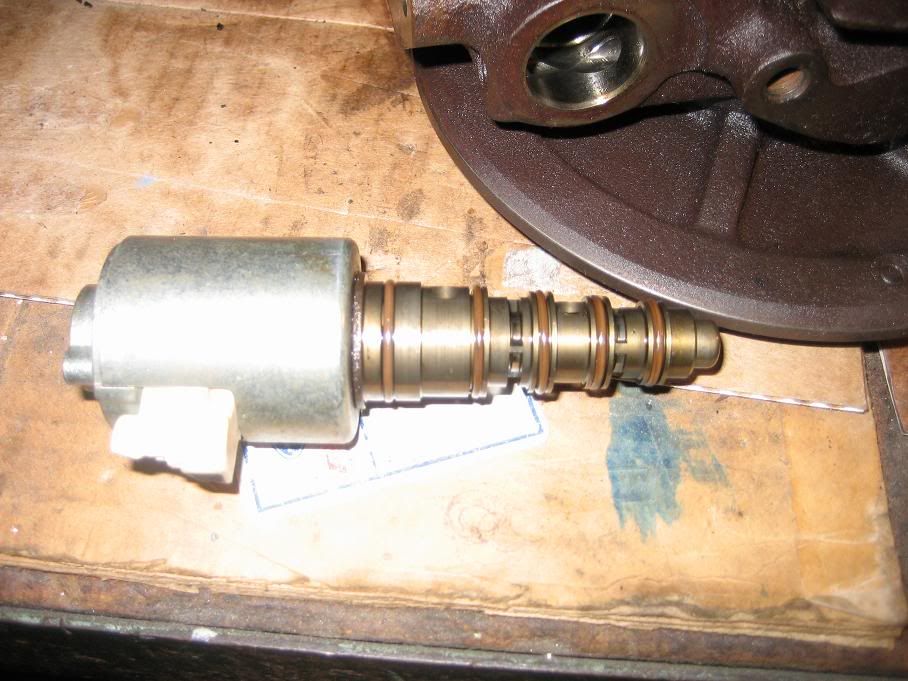

The center housing is quite weird compared to normal turbos. The large piston that moves the vanes is large. I like the clever single solenoid valve that provides infinite control over vane position.

After its balanced, I have to reclock the turbine housing in one of nine positions due to the nine vanes. A strategic hole lines everything up. Also, I have to weld an AN fitting to the oil drain since the Powerstroke uses a tube with an O-ring.

I haven't had much progress lately because baby needs camshafts and a plate or two for the clutch. I'll work on the engine bay this week, installing the pedal box, brake master cylinder, clutch master, lines, some wiring, etc.

The other day I disassembled the turbo for cleaning. I'm not sure if it needs to be apart for balancing, but I'll find out tomorrow. Anyways, she's in pretty nice shape. No play or scoring on the bearings, and it happens to have a 360 degree thrust bearing. I was surprised as to how heavy the turbine wheel is. Its crazy that it spins up to 115,000 rpm.

The center housing is quite weird compared to normal turbos. The large piston that moves the vanes is large. I like the clever single solenoid valve that provides infinite control over vane position.

After its balanced, I have to reclock the turbine housing in one of nine positions due to the nine vanes. A strategic hole lines everything up. Also, I have to weld an AN fitting to the oil drain since the Powerstroke uses a tube with an O-ring.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Made a little progress the other night. The brake master and pedal box is a serious pain without an extra set of hands.

In a few weeks I can get some turbo cams and a top plate for my clutch, so I can put the motor in for good and rework the pipe set once again for this turbo. Then its on to wiring and other basic plumbing, and finishing the fuel system. And finally, paint once it get warm here in MN. My garage is heated, but it would blow way too much crap around to paint, nor could it keep up with my overspray exhuast setup.

In a few weeks I can get some turbo cams and a top plate for my clutch, so I can put the motor in for good and rework the pipe set once again for this turbo. Then its on to wiring and other basic plumbing, and finishing the fuel system. And finally, paint once it get warm here in MN. My garage is heated, but it would blow way too much crap around to paint, nor could it keep up with my overspray exhuast setup.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

Overspray sucks major ass.....

Josh

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

I decided to experiment a little more, since the price was right.

I picked up a '07 Duramax turbo on ebay for $150. It even comes with the VNT solenoid, which is $360 new, and the vane position sensor also comes with. I'll see about logging the vane position with my Link.

It should be fun to disassemble in a week or two. I'm also curious as to the size of the compressor wheel. The housing is slightly different than the Ford units, and obviously has the 11 full-blade compressor wheel like the new GTX series turbos.

I hope it all fits together like I'm planning. Duramax center housing, Powerstroke exhaust housng and wheel, and a GT4088R compressor wheel, housing, and backing plate. We'll see in a week or two.

The oil inlet uses a banjo on the Duramax instead of the usual T-series inlet flange. A -4 AN to whatever those threads are shouldn't be an issue. .

Here you can see the inlet and outlet for the coolant. They use banjo bolts on the Duramax application. The oil drain uses a nice standard oil drain flange, from the looks of things. It may save me from welding a -10 fitting to the housing itself

I picked up a '07 Duramax turbo on ebay for $150. It even comes with the VNT solenoid, which is $360 new, and the vane position sensor also comes with. I'll see about logging the vane position with my Link.

It should be fun to disassemble in a week or two. I'm also curious as to the size of the compressor wheel. The housing is slightly different than the Ford units, and obviously has the 11 full-blade compressor wheel like the new GTX series turbos.

I hope it all fits together like I'm planning. Duramax center housing, Powerstroke exhaust housng and wheel, and a GT4088R compressor wheel, housing, and backing plate. We'll see in a week or two.

The oil inlet uses a banjo on the Duramax instead of the usual T-series inlet flange. A -4 AN to whatever those threads are shouldn't be an issue. .

Here you can see the inlet and outlet for the coolant. They use banjo bolts on the Duramax application. The oil drain uses a nice standard oil drain flange, from the looks of things. It may save me from welding a -10 fitting to the housing itself

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

Cool!

Looks interesting to say the least.

Looks interesting to say the least.

Josh

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

The Duramax turbo was disassembled last night. Long story short, a Powerstroke/Duramax hybrid turbo will not work without some machining.

The two turbos are very similar, but very different at the same time. They use the same VNT system, but the turbine and compressor setups are quite different. The Duramax turbo uses a short little shaft with the compressor extending into the center housing with the sealing ring acting on the outside of the wheel to seal the compressor side from oil. The turbine wheel is a backwards step in technology with a straight inducer. The compressor is larger (GT3788) and has 11 blades for higher flow for the extra .6 L of displacement. Their decision to completely change the sealing and shaft design is quite odd though.

The turbine wheel is surprisingly short, with more blades. The lack of curvature on the inducer has me scratching my head though. I could machine the center housing to accept the Powerstroke wheel as the bearing system is the same, albeit a 360 degree thrust bearing, but I really don't feel like getting into that business. The water cooling would be nice, but I'd rather not dive in that far.

So in the end I'll be sticking with the powerstroke center housing, but I might keep the vane position sensor. I'll probably rebuild the Duramax turbo so I can at least get my money back on the thing.

Pics:

One area if interest is the advanced aerodynamics of the compressor backing plate. It is tailored to a specific position of the compressor, and isn't really meant to be clocked. However, the backing plate is cast to suit this specific application directly, as seen my the shape of the surface.

The two turbos are very similar, but very different at the same time. They use the same VNT system, but the turbine and compressor setups are quite different. The Duramax turbo uses a short little shaft with the compressor extending into the center housing with the sealing ring acting on the outside of the wheel to seal the compressor side from oil. The turbine wheel is a backwards step in technology with a straight inducer. The compressor is larger (GT3788) and has 11 blades for higher flow for the extra .6 L of displacement. Their decision to completely change the sealing and shaft design is quite odd though.

The turbine wheel is surprisingly short, with more blades. The lack of curvature on the inducer has me scratching my head though. I could machine the center housing to accept the Powerstroke wheel as the bearing system is the same, albeit a 360 degree thrust bearing, but I really don't feel like getting into that business. The water cooling would be nice, but I'd rather not dive in that far.

So in the end I'll be sticking with the powerstroke center housing, but I might keep the vane position sensor. I'll probably rebuild the Duramax turbo so I can at least get my money back on the thing.

Pics:

One area if interest is the advanced aerodynamics of the compressor backing plate. It is tailored to a specific position of the compressor, and isn't really meant to be clocked. However, the backing plate is cast to suit this specific application directly, as seen my the shape of the surface.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

Interesting work on the turbos Dan. Too bad that duramax didn't work.

Are there any gasoline engines that are using VNT technology?

Are there any gasoline engines that are using VNT technology?

Josh

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

surrealmirage.com/subaru

1990 Legacy (AWD, 6MT, & EJ22T Swap)

2020 Outback Limted XT

If you need to get a hold of me please email me rather then pm

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

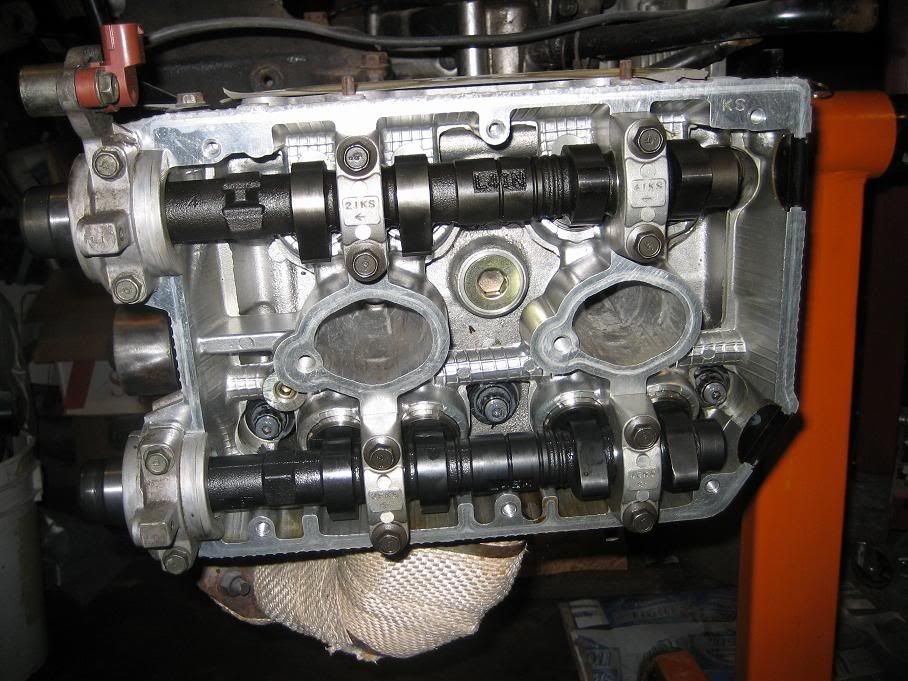

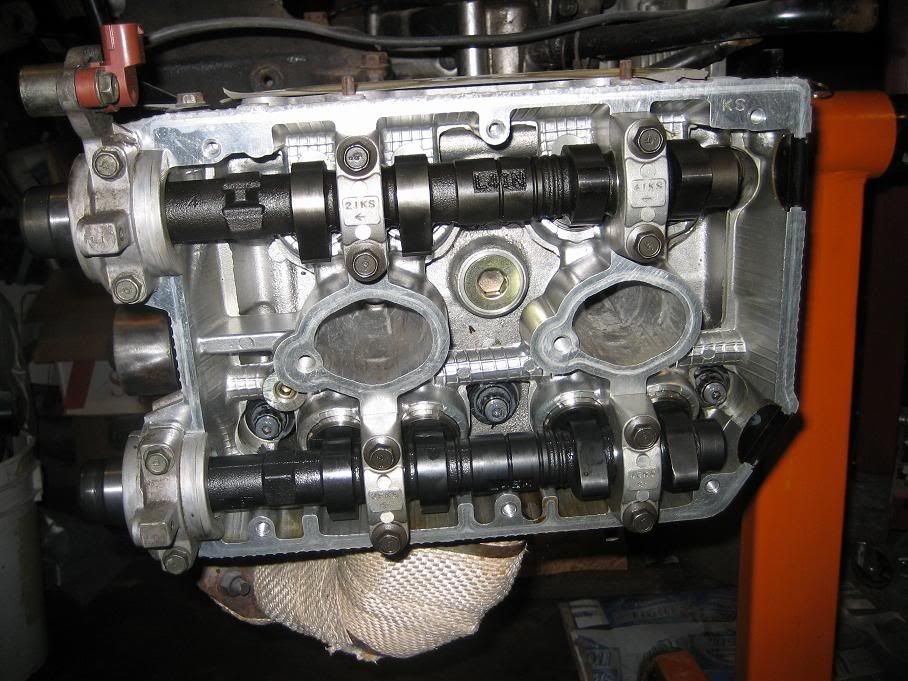

Tonight I test fit the EJ20K camshafts and checked the valve lash. Only one shim needs to be adjusted, FTW.

Notice the longer duration and different overlap of the EJ20k cam on the right. THe cams are out of a STi Version 4, I think. I would like the Spec-C cams of that vintage, but they are hard to come by. Also, the 20K cams don't have offset lobes. The 25D cams have offset lobes, and on the exhaust cam, the lobes have different durations for each cylinder. Good riddance.

One of the cams I had to have repaired by Delta Cam. I bought them with one of the bearing journals torn up. $35 fixed that, and now I have turbo cams. N/A cams suck for boost. Waaaay too much overlap means lots of boost, fuel, and air blown straight into the exhaust. Your wideband says you are leaner than you really are.

I've got this next week off, so I hope to make serious progress in the next five days. Motor and tranny in the car, and work on the pipe set. I can finally put my turbo back together (after a $50 thrust bearing), and get crackin. Then fuel system stuff and wiring. We'll see how far I get and what hangups come about.

Notice the longer duration and different overlap of the EJ20k cam on the right. THe cams are out of a STi Version 4, I think. I would like the Spec-C cams of that vintage, but they are hard to come by. Also, the 20K cams don't have offset lobes. The 25D cams have offset lobes, and on the exhaust cam, the lobes have different durations for each cylinder. Good riddance.

One of the cams I had to have repaired by Delta Cam. I bought them with one of the bearing journals torn up. $35 fixed that, and now I have turbo cams. N/A cams suck for boost. Waaaay too much overlap means lots of boost, fuel, and air blown straight into the exhaust. Your wideband says you are leaner than you really are.

I've got this next week off, so I hope to make serious progress in the next five days. Motor and tranny in the car, and work on the pipe set. I can finally put my turbo back together (after a $50 thrust bearing), and get crackin. Then fuel system stuff and wiring. We'll see how far I get and what hangups come about.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

Re: UHEV Legacy Version 2.0

really dig what you are doing with this vnt stuff. seems like very few are using them yet. if you can get that link to drive the VNT solenoid that will kick major ass and it will probably feel like you have a v8 under the hood from the low end.

1994 Touring Wagon: ruby mica, 5mt swapped

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

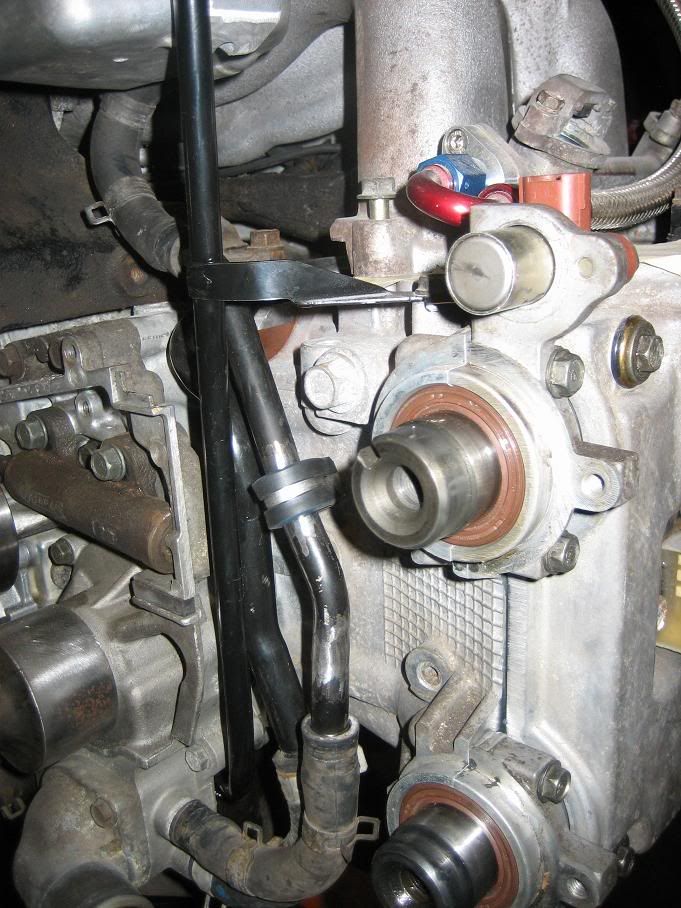

Trans is in the car, for good. The turbo CHRA is also assembled and ready for media blasted housings. I had to weld a -10 oil drain fitting to the center housing before I could assemble the CHRA.

I spent half of the day running all over the Twin Cities, so I couldn't get the motor buttoned up and in. I did remove, clean, and reinstall one cylinder head though. Long story....

I spent half of the day running all over the Twin Cities, so I couldn't get the motor buttoned up and in. I did remove, clean, and reinstall one cylinder head though. Long story....

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

206er wrote:really dig what you are doing with this vnt stuff. seems like very few are using them yet. if you can get that link to drive the VNT solenoid that will kick major ass and it will probably feel like you have a v8 under the hood from the low end.

Derek (whitelegacyguy) pioneered the use of this turbo, so I had to jump on board. It does work, and works quite well. We spent all last summer figuring out the map for the vanes. Just search youtube for "GT3782", and you'll see most of the videos.

His car does drive like a V8. Boost starts at 2500 rpm and rises fairly linearly to 28 psi at 4000 rpm. His car (SS with a highly built auto) is deceptively fast since the turbo comes on so smooth. He desperately needs cams though. The 25D cams are killing the power right now. I bug him every other day, but he just bought a STS-V. Bastard.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

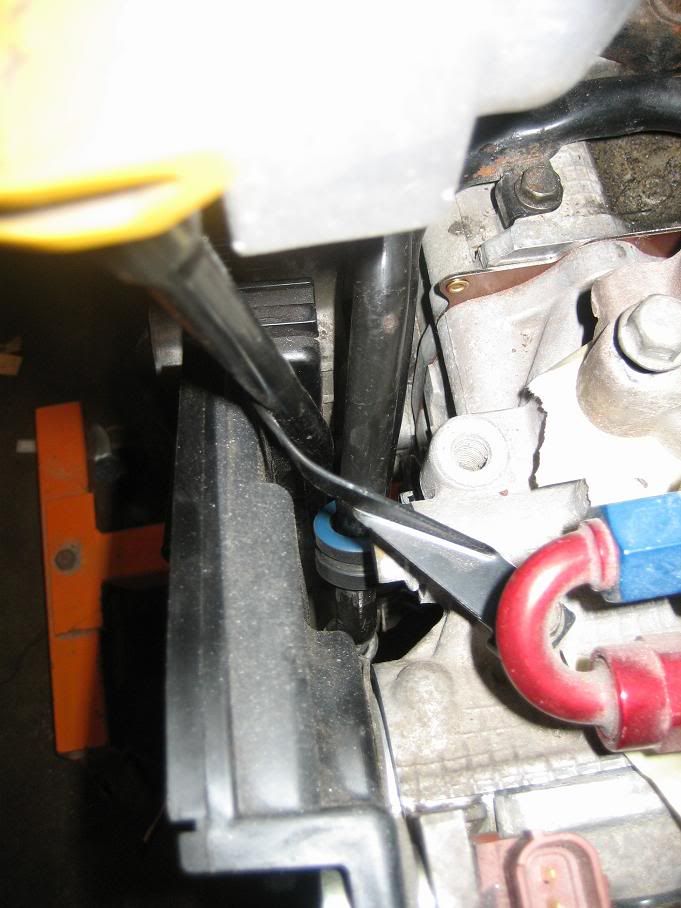

Trying to diagnose other cars means less time for mine. I still got some work done though.

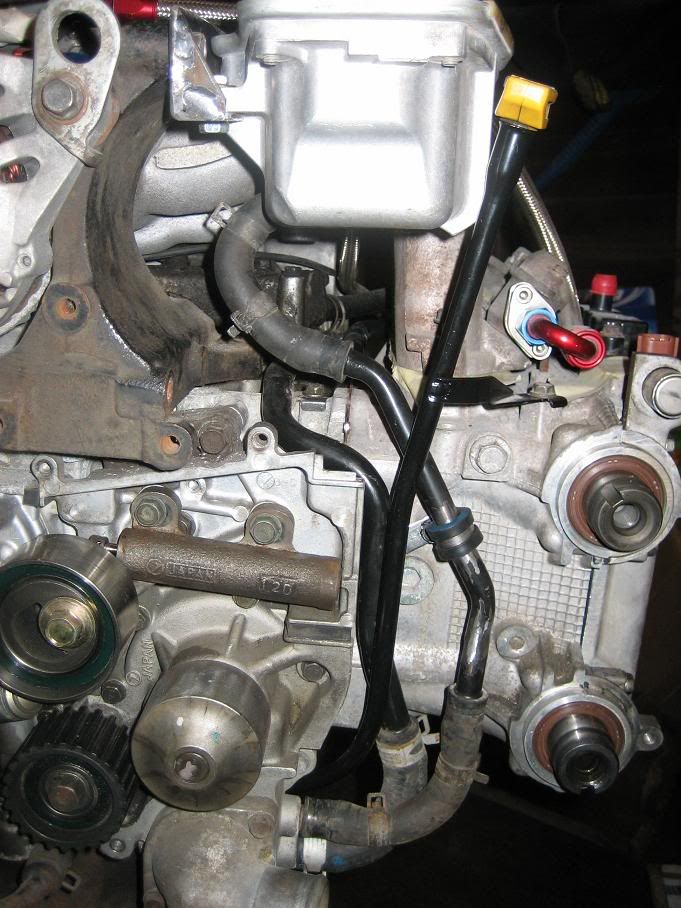

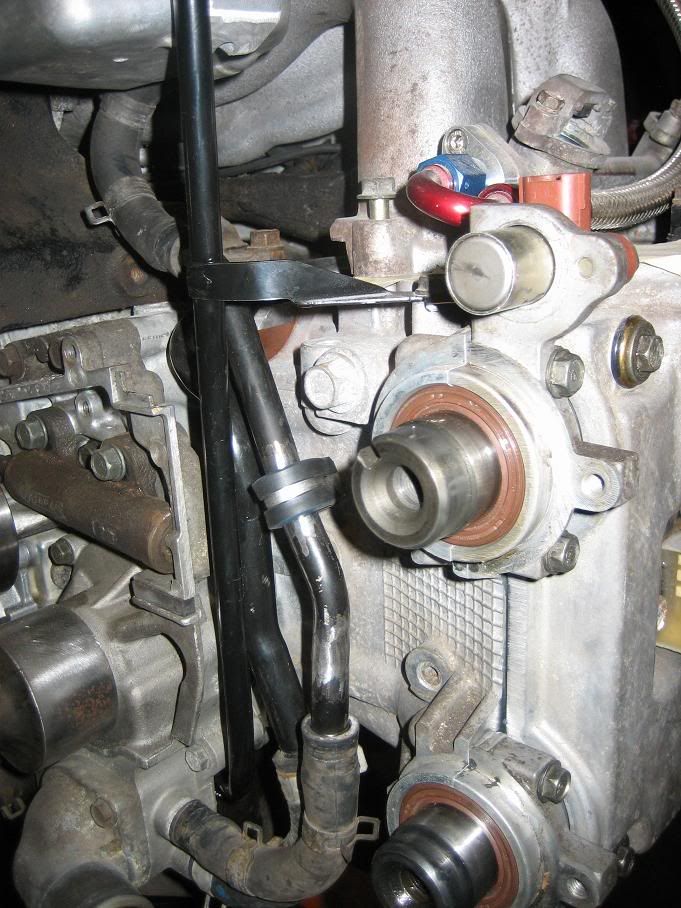

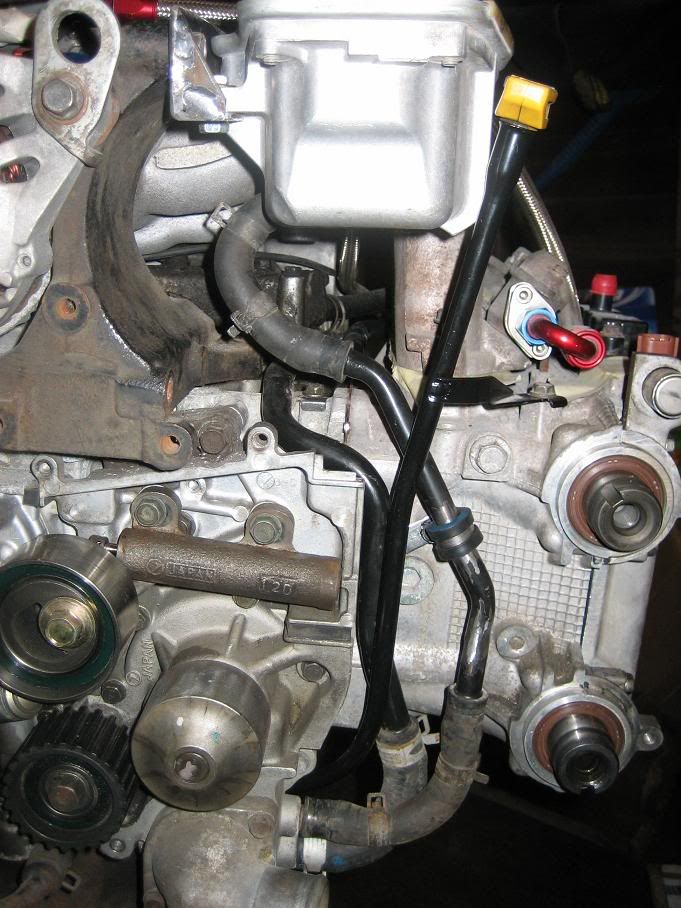

The cams are all buttoned up and what not. I ran into an issue with the EJ25D coolant hard pipes. The EJ22T runs a smaller tube over the top of the head which connects to the throttle body and coolant expansion tank, and runs a larger tube under the head for the heater core. The lower tube does not fit the 25D head without modifying the brackets. I could have done that, but I had other ideas.

I decided to mount a WRX expansion tank where the AC compressor was. I would have had to run a hose from the back of the motor to the front for the tank, but that would be lame. I cut apart the smaller EJ22T tube and reworked it to run straight up to the tank. It worked out pretty well I think.

I also went to Fobia's to do some cleaning last night. I wasn't feeling the black color on the compressor housing, so I took that off. The exhaust housing was cleaned, even though it kinda pointless unless I get it coated. Not this year.

I also had him fuse two flanges together for the turbo inlet, since I seem to have a problem with warping 3" v-band flanges. :dunno: I'm ready to go for reworking the piping, however. Picked up a turbine outlet from Diesel Components for cheap. That place rocks btw.

The cams are all buttoned up and what not. I ran into an issue with the EJ25D coolant hard pipes. The EJ22T runs a smaller tube over the top of the head which connects to the throttle body and coolant expansion tank, and runs a larger tube under the head for the heater core. The lower tube does not fit the 25D head without modifying the brackets. I could have done that, but I had other ideas.

I decided to mount a WRX expansion tank where the AC compressor was. I would have had to run a hose from the back of the motor to the front for the tank, but that would be lame. I cut apart the smaller EJ22T tube and reworked it to run straight up to the tank. It worked out pretty well I think.

I also went to Fobia's to do some cleaning last night. I wasn't feeling the black color on the compressor housing, so I took that off. The exhaust housing was cleaned, even though it kinda pointless unless I get it coated. Not this year.

I also had him fuse two flanges together for the turbo inlet, since I seem to have a problem with warping 3" v-band flanges. :dunno: I'm ready to go for reworking the piping, however. Picked up a turbine outlet from Diesel Components for cheap. That place rocks btw.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

Whew. Motor together, clutch on, and in the car. It always takes longer than I expect when I do it by myself. I probably spent an hour putting the clutch on the motor, figuring out a good method to keep it lined up and all. There is definitely a knack to doing it quickly. Lining up the motor to the trans was fun too. It took a lot more adjustments than usual to have it slide together.

Soon I should be able to start the fun stuff. Modifying the pipe set for the turbo *shouldn't* be too bad, since I'm not starting from scratch.

Soon I should be able to start the fun stuff. Modifying the pipe set for the turbo *shouldn't* be too bad, since I'm not starting from scratch.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

93forestpearl

- Fifth Gear

- Posts: 3043

- Joined: Tue Jan 25, 2005 9:14 pm

- Location: Twin Cities, MN

Re: UHEV Legacy Version 2.0

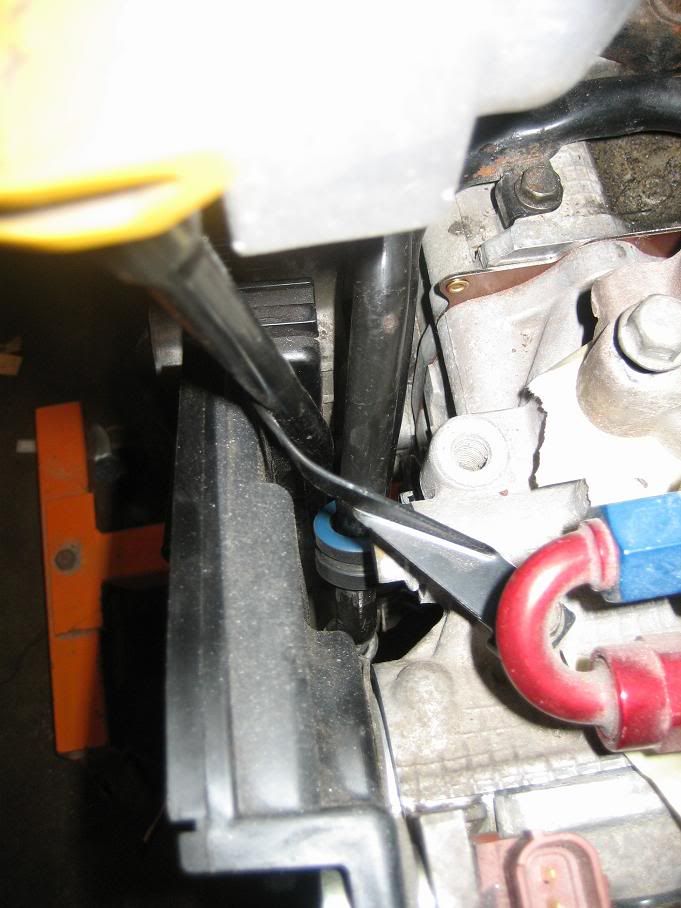

This stuff is pretty neat. It's like a big roll of masking tape, but with the adhesive strength of slightly more than post-it notes.

→Dan

piddster34 at h0tma1l d0t c0m

piddster34 at h0tma1l d0t c0m

-

SubaruNation

- Fifth Gear

- Posts: 3526

- Joined: Wed Jul 18, 2007 5:07 pm

- Location: Whammy!

Re: UHEV Legacy Version 2.0

still interested in teh UHEV sticker if you are making them! progress is sweet im stoked for ya!

Zach - Legacy Frankenstin

93forestpearl wrote:Keep up the good work. You'll never know what you are capable of unless you push yourself.